IV. Things That Cause Clearance Values to Change

Normal wear on the impeller vanes and the interior surface of the pump bowl are typically the result of the abrasive action of moving water, especially river water containing sand and other suspended solid particles. In general, this type of wear tends to cause pump clearances to increase over time, which consequently causes the pump efficiency to decrease over time.

At Cooper Nuclear Station, typically the intake water contains 0.1 to 0.3% solid particles by volume. Thus, for every 120 gallons of water pumped, there will also be 1.28 to 3.8 pounds of abrasive sand and sediment pumped along with it. Clearance losses of this type usually occur gradually over time.

As already discussed, wear on the impeller and bowl can also be caused by the clearance between the impeller and bowl being too tight. This type of accelerated wear occurs rapidly, and will cause a corresponding loss of pump performance to occur in a relatively short period of time.

B. Relative Expansion and Contraction

If the impeller, impeller shaft, bowl, and flow tube are made of different materials, and the pump assembly and reservoir are located outside in an uncontrolled environment where there are significant temperature changes, like in a river, it is likely that the assembly will experience differential expansion and contraction. A lift adjustment made when the river temperature is hot may not be within tolerance when the river temperature is cold, and vice-versa.

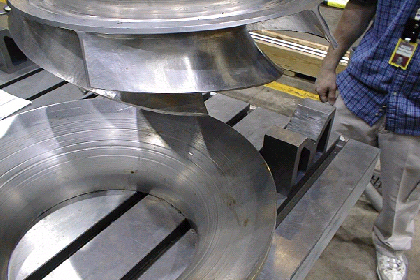

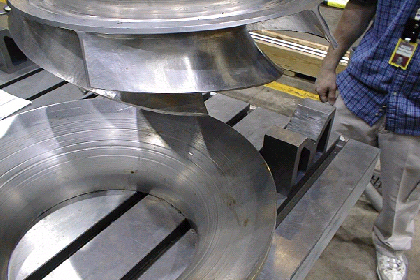

Figure 2. Gouging in impeller bowl due to expansion and

contraction effects of Impeller shaft.

For example, the Service Water Pumps at Cooper Nuclear Station have an overall length of about 46 feet from motor coupling to the bottom of the impeller. The pump shafts are made of hardened 410 stainless steel which has an expansion coefficient of about 5.5 x 10-6 in per in per oF. On the other hand, the AISI 1030 cast steel flow tube has an average expansion coefficient of about 8.3 x 10-6 in per in per oF. During the winter, the minimum intake water temperature to the Service Water System is about 35 oF. During the summer, the maximum temperature is about 90 oF. Thus, the greatest relative expansion or contraction between the Service Water pump shaft and the flow tube due to the extremes of weather is estimated as follows.

(ix) dL = (a)*(dT)*L

dLtube = (46 x 12 in)(8.2 x 10-6 in per in per oF)(55 oF) = 0.249 inches

dLshaft = (46 x 12 in)(5.5 x 10-6 in per in per oF)(55 oF) = 0.167 inches

Difference = 0.082 inches or 82 mils

Thus, if the pump is set to a lift position of 40 mils during the summer on the hottest river day and no further lift adjustments are made, the pump impeller will grind itself into the pump bowl to a depth of 42 mils by the time the coldest river day occurs. This will, of course, cause accelerated wear in the both the impeller and bowl, and significantly shorten the service life of the pump.

Similarly, if the pump is set to a lift position of 40 mils on the coldest river day and no other lift adjustments are made, the clearance will open to 122 mils by the time the hottest river day occurs. This will cause the output pressure and the Total Developed Head to slowly drop over a six month period.